Zygo Metrology Systems Support Virtual Reality Product Development

A global VR solutions provider, relies on Zygo for optimal results. Captain Lin, a key figure within the company, highlights the necessity of Zygo’s technology for intricate adjustments, ensuring unparalleled quality in headset lenses and cellphone screens.

Elevating Virtual Realities

Zygo prides itself in ensuring Virtual reality (VR) creates a fully immersive experience that allows users to feel like they are actually in the virtual world. This is done by using headsets that block out the user’s real-world surroundings and display a computer-generated world in their field of view.

Zygo’s client with operations in the United States, Europe, China, and Japan develops innovative (VR) solutions that enable users to experience the best in VR and immersive reality technologies. As the company develops new products on its optics, metrology was extremely important to Captain Lin, a former director at the company.

Metrology tools for immersive reality devices quantify surface form, diffraction angles and efficiency, assembly tolerances, and surface roughness, and assist in development and prototyping, performance evaluation, and production quality control.

“Creating VR products utilising headset lenses and cellphone screens requires extreme precision. That’s why we need the best metrology equipment available,” said Captain Lin. “My skill is in using metrology equipment that can perform complex calculations to help manufacturers adjust their mold base or their compensation for lens deviation so that we get optimum results. When I use Zygo’s equipment and software, everybody trusts the results. That’s why I love using Zygo to analyse things,” he added. To ensure that it was using the best equipment for the task, the company turned to Zygo, the leading optical metrology innovator.

Optimising VR Precision

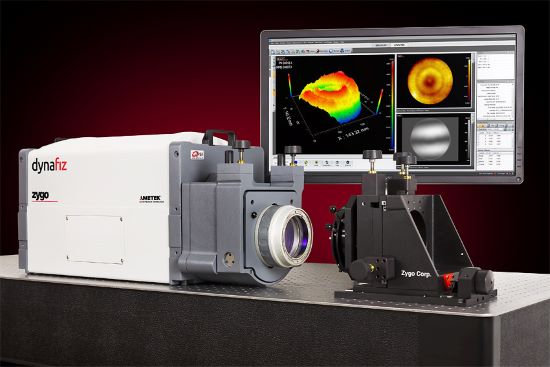

Zygo recommended that the VR solutions company use its DynaFiz® Laser Interferometer. Purpose-built for reliable interferometry in vibration-prone environments, this equipment is versatile and flexible enough to address a wide range of application needs, from high-end telescope testing to live phase feedback for active alignment of optical systems. Its fully coherent optical design enables highest light efficiency, improving dynamic performance

Read more here at page 44

What You Missed:

Rever Automotive Builds And Tests BYD Buses In Thailand

Tesla Cuts More Than 10% Of Its Workforce

Tesla Settling Lawsuit Erodes Faith In Autonomous Driving

IoT Offers A Wealth Of Opportunities

High Household Debt In Dips Thailand Automotive Production And Sales

AST Begins Constructing Singapore Facility For High-End Substrates & Advanced Technologies

eVTOL Aircrafts May Dominate The Skies

Get To Zhuhai From Shenzhen In 20 Minutes With AutoFlight

Wire 2024 in Düsseldorf: Electrifying Prospects for Cables

Cover Focus – Milling with “Xtended Technology” – Xtra·tec® XT

wire and Tube 2024 To Set New Standards

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

CONNECT WITH US: LinkedIn, Facebook, Twitter

Letter to the Editor

Do you have an opinion about this story? Do you have some thoughts you’d like to share with our readers? APMEN News would love to hear from you!

Email your letter to the Editorial Team at [email protected]