Artificial Intelligence In Bending

Manufacturers are now adopting artificial intelligence (AI) to further create value for the customers. But how would AI be applied to sheet metal bending? In this article, Melvin Tham, Regional Technology Expert – Bending, for TRUMPF, explains.

Using conventional press brakes to achieve high accuracy for sheet metal is challenging due mainly to the property of the material, where its elasticity varies according to its composition and grain direction. Therefore, the process would usually take a longer time as it requires more knowledge and skill in order to achieve higher accuracy.

In today’s industrial environment, machines are loaded with functions to ensure that the manufactured parts are precise and consistent with minimal human/operator intervention, and manufacturers are now adopting artificial intelligence (AI) to further create value for the customers. But how would AI be applied to sheet metal bending?

Automatic Set Up

Given the current high-mix, low-volume market demand, the system must be easily set up within minutes to cater for a job change over. Therefore, a self-centring tooling system would be most ideal. With an automatic tool changer, there is no longer a need for alignment as the tools are automatically placed in position and integrated into the machine. It has three to four times more storage capacity than the machine’s bending length, all just to ensure a quick changeover and without the hassle of tool shortage.

Positioning and Angle Accuracy of Part

Since the bending process is now automatic, the quality of the parts has to be checked automatically as well. Such system would require high dynamic functions such as the backgauge. The backgauge with an axis tolerance of ±0.02 mm and the angle sensor tool with tolerance at ±0.5 deg are required to ensure that the part is placed accurately in position and angle tolerance is achieved by an angle checking device.

Sensors of the backagauge are necessary for the identification of the part in position. Without this, the part would not be able to achieve its desired flange length.

An automatic detection of the angle needs to be equipped to determine the correct angle to be achieved for each bend. With Automatic Controlled Bending (ACB), the total completion time to bend, calculate and adjust will take less than a second!

Identification of Parts and Positioning Compensation

The system must be able to detect the correct part to pick up and automatically determine the datum point to compensate positioning error. It is important to define the datum point so that all bending sequence and positioning accuracy can be referenced.

Although a structured stand that pre-fixed the part datum point can be achieved, the best possible solution will be with a high-resolution and precise camera profile detection that is flexible and automatic. This camera device could detect the sheet stack, height and fine profile of the part for single sheet without the need to specifically prepare sheet in a fixed position. With such function, a lot of time is saved from the preparation for defining, picking and loading of parts.

Gripper Technology

The grippers picking up the parts are of critical importance as well. Our grippers are designed with the concept of holding the parts as firmly as a human hand would. The gripper can be used for multiple parts and the suction cups can be pneumatically turned on or off to cater to different profiles and gripping area.

CAM-assisted Offline Programming

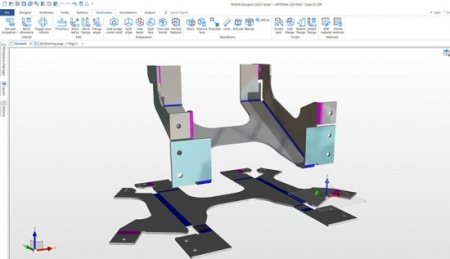

Software plays a very important role in automation. It should be able to strategically control all movement offline with intuitive graphical teaching.

In the past, robot movements are codings that are entered line by line in order to perfect a smooth travel path. With advanced software like TruTops Bend Automation, not only are we are able to graphically teach the movement from one point to another, we can also teach the robot to flip, load and unload the part. The software enables us to run a simulation prior to the actual process.

Robotic Movement and Payload

There are many robotic equipment in the market, with some having more than eight axis of movement and payload of more than 1,000 kg! So how do we know which is suitable?

In bending, it is always the working area within the press brake and robotic system. The bigger the working capacity means there is a better flexibility on the type of profile that can be bent.

The longer the trackway of the robot arm, the more parts can be prepared for loading and unloading. This is to ensure that the machine is always filled with part for continuous production and not idling or waiting for parts. There are also possibilities that the finish part can be stacked in cage or drop box.

The higher the payload means a bigger robot arm would be required. When the arm gets too big, there is a minimum distance of limitation due to the kinetic movement, therefore small parts cannot be picked up. Hence, it is important to define the size of the product before the selection of the automatic bending cell. This will make it easier to select the type of press brake and robotic arm for the job.

With all the necessary functions that are in place to ensure the output quality of the parts, the production is all ready for artificial intelligence bending!

For other exclusive articles, visit www.equipment-news.com.

Check these articles out:

Blechexpo/Schweisstec 2019 Concludes With Record-Breaking Dimensions

Laser Cutting In An 8-metre Format

Bystronic Releases BySmart Fiber In 4020 Format

TRUMPF Discusses Opportunities For Growth In Vietnam

Integrated Measurement Technology For Maximum Quality

Modular Power Package For Demanding Benders

Artificial Intelligence Software Market To Reach US$118.6 Billion By 2025

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter