Schaeffler is meeting the challenges of the machine tool industry with new automation solutions that are characterised by even greater dynamics, precision, energy efficiency, and longer machine runtimes.

Tesla Leverages Malaysia Tariff Liftings For A Later Grand Entrance

Tesla’s Model Y has made it into Malaysia – according to reports priced at about RM 200,000 (S$88,000). The cars are still assembled in China for obvious reasons. However, manufacturing may shift to Malaysia in due course.

Milling Instead Of Grinding With The Hand Angle Miller

The wide range of milling discs, special techniques when milling by hand, as well as the use with hand angle millers and in (partially) automated processes. The milling discs are available in the three different kinds “milling disc”, “double sided milling disc” and “doubleworker”, which aim different areas of application.

For all of those the following applies:

The surfaces processed with the discs are metallic bright, and therefore prevent cavities while welding. While working, the discs produce neither (unhealthy) dust nor heat, and thus no structural changes that come with heat. The amount of material removed and the fineness of the result depend on the toothing. The fewer teeth, the coarser the chips and the greater the amount of material removed. The more teeth a disc has, the finer the chips and the smoother the surface, but less material is removed. The specific toothing depends on the material to be machined and the disc size.

The discs can be used for the following tasks:

- The milling disc gets used for bevelling, deburr and flatten as well as working out weld roots.

- The double sided milling disc (DMD) is used to open weld roots, according to the literal translation of the German original description, that would be “weld root opener”. Due to the teeth geometry, it is not made for the tasks performed by a single sided milling disc.

- The Doubleworker (DW) combines the scope of single and double sided milling discs, without the need to frequently change the tools. The teeth geometry of the double sided milling disc had been adjusted to resolve the problem of chips getting stuck in the chip chamber.

Maija-Frästechnik GmbH, founded in 2012, develops, produces and sells high-quality milling tools made of hard metal. The company owns the patent for milling discs, which was registered in 2000 by the later company founder.

TMR: CNC Market to Reach $115B by 2027

The increasing focus on production efficiency is aiding the uptake of computer numerical controls (CNC) technologies as these machines streamline various operational processes by reducing production time and minimizing human error.

The highly competitive environment has compelled players to focus on efficient manufacturing techniques. They are also trying to gain competitive advantage by redesigning their manufacturing facilities to include CNC machines. The integration of 3D printing with CNC machines is one such addition to some of the new production units, which is expected to offer better product design with little to no resource wastage.

Fuelled by these factors, the global market for computer numerical controls is projected to grow from a value of $64 billion in 2018 to $115.1 billion by 2027, according to a study by Transparency Market Research (TMR). If these values hold true, the CNC market is expected to register a CAGR of 6.7 percent during the forecast period.

READ: Are Cheaper CNC Machine Tools More Cost Effective?

READ: COVID-19 Updates: Auto Makers Revving Up Production To Drive Market Recovery

Automated Manufacturing Driving Demand for CNC in Industrial and Automotive Sectors

Based on type, the global CNC market is led by lathe machines, and the segment is poised to dominate the market throughout the forecast period. The demand for lathe machines can be attributed to a wide application area.

On the other hand, milling machines are anticipated to register a strong growth rate during the forecast period. Milling machines are compatible with a wide range of materials and surfaces and help improve overall efficiency. Furthermore, technological innovation has led to the development of advanced milling machines that can provide a more consistent finish to the products.

In terms of application, the industrial segment held the dominant share and is likely to retain its lead through 2027. The growing demand for automated manufacturing in the industrial sector resulted in the increasing uptake of CNC machines. The establishment of manufacturing facilities in developing regions such as Asia Pacific has also spurred the usage of CNC technologies in this sector. The automotive sector, on the other hand, is set to be the most rapidly developing segment in the coming years thanks to the soaring rate of automated automobile manufacturing.

North America Continues to Present Immense Scope Despite Market Saturation

From a geographical viewpoint, the global market for computer numerical controls is led by Asia Pacific, with the region accounting for a share of approximately 35 percent in 2018. Developing economies such as China and India have been witnessing robust growth in terms of industrialization, thereby propelling the regional market. The automotive sector has been estimated to register rapid growth in the Asia Pacific CNC market during the forecast period owing to the rising demand for automobiles in the region. In addition, the easy availability of labour and the declining prices of components have resulted in manufacturers shifting their production units in this region. This is further propelling the APAC CNC market.

READ: CNC Control for Rolling Machines

READ: Standardisation of Mould Bases

Meanwhile, considering that the United States is the one of the earliest adapters of new technologies, the North America market for CNC machines is relatively saturated. Be that as it may, rising concerns over global warming and depleting energy reserves have led to the production of alternative sources of power such as solar, water, and wind, and this has significantly upped the demand for CNC machines in the region. CNC machines are actively used in power generation as the process requires wide-scale automation.

Key Driving Factors, Promising Avenues, and Challenges

Some of the key growth dynamics in the CNC market are:

- The drive for automated manufacturing in various industries is a key trend driving the expansion of the CNC market.

- Industries, notably automotive, have increasingly adopted automated machine control technologies to improve operational efficiencies and reduce overall costs.

- In numerous developing and developed countries around the world, growing emphasis on reducing the carbon footprint of manufacturing has spurred growth in the CNC market.

- Over the past few years, deployment of 3D manufacturing technologies have been at the forefront for industries, bolstering demand for CNC.

Despite the attractive potential of CNC in industrial automation, such technologies require substantial investment. The maintenance and servicing is also cost-intensive, resulting in small-scale enterprises to avoid the adoption. All these are proving to significantly constrain the growth of the CNC market.

On the other hand, the incredible drive for efficiency gains is a key business proposition for the rise in demand in the CNC market.

For other exclusive news and information, visit www.equipment-news.com.

Check these articles out:

Manufacturing In Asia Post COVID-19

Aftermarket Services Could Help Transform Manufacturing In The Wake Of The COVID-19 Pandemic

PC-Based Control For Covid-19 Rapid Testing Production Lines

[WATCH] Siemens Discusses Initiatives, Outlook Amid COVID-19

Mouldmakers Turn To Process Automation In Race To Recover

Getting Back To The Roots: Revisiting Applications CNC Machines

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter

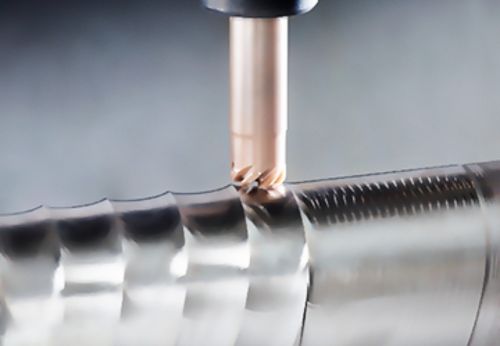

Walter Tools Releases White Paper on Dynamic Milling

Walter Tools has released a new white paper on the advantages and benefits of dynamic milling. Higher process reliability, and shorter machining times at ever lower costs—many industries, especially suppliers, are in this dilemma. In addition, there are always new materials, driving the need for weight savings, corrosion resistance and resistance to very high temperatures. And then there are materials that are often difficult to machine.

For all of these, dynamic milling offers a solution that promises both higher productivity and higher process reliability under the right conditions. In a new whitepaper, Walter Tools discuss the advantages of dynamic milling compared to other milling processes. It also highlights all the facts that you need to know about the process, including prerequisites, technologies in comparison, and effects, among others.

For more information, click here.

Check these articles out:

Walter: Insert Grades WPV10 And WPV20 For Perform Turning Tools

Walter: Carbide Drilling Tools

Walter’s HU5 Geometry Enhances Capabilities Of Cutting Machines

New Geometry And Special Post-Treatment Increase Tool Life of Walter Thread Former

Walter Celebrates 100 Years Of Innovation

Walter MX System For New Applications And Possibilities

Walter AG Releases New X.treme Evo Solid Carbide Drill With Threefold Universal Use

Tools At The Touch Of A Button

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter

ISCAR Launches Chipformer For Finish Turning On Superalloys

Intended mainly for aerospace industries as well as for the oil and gas market, the F3S chipformer—the new efficient chip breaker from Iscar—is designed for working with unique and tough-to-machine nickel-based alloys, such as Inconel, Waspaloy, etc., as well as other exotic materials such as titanium-based alloys.

The new F3S chipformer from Iscar has a positive rake angle to ensure a smooth and easy cut, with significant reduction in cutting forces and notable chip breaking results. The F3S chipformer has been designed with geometric features to improve tool life, with a reinforced cutting edge at the area where VG (notch wear) wear tends to occur when machining superalloys and exotic materials, which causes poor surface finish and risk of edge breakage.

The chipformer is available on the most popular inserts – CNMG, WNMG and SNMG – in two main grades, IC806 and IC804, and will be available in the future also on VNMG, DNMG, and TNMG inserts.

CHECK OUT THESE OTHER ARTICLES

● The World Of Tube Processing

● OMAX Presents Waterjet Cutting Technology at EMO 2019

● Vietnam To Remove Import Tax For Auto Materials

● Iscar Expands Modular Exchangeable Drilling Heads Lineup For Large Diameter Deep Drilling

● Singapore’s 50.8 PMI Reading Sees Ninth Consecutive Month Of Expansion

● Siemens Invests In New Materials Solutions Facility

● Sandvik Coromant To Showcase Digital Solutions For Machining Processes At EMO 2019

● Machining Miniature Medical Parts

● Global Aerospace Materials Market To Reach US$10.8 Billion By 2025

● Cutting Tool Inserts To See Ballooning Sales

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter

Tungaloy Expands Copy Milling Cutter Diameter Lineup

Tungaloy is expanding its DoTwistBall line of copy milling cutters to include additional diameters of shell mills.

The DoTwistBall copy milling cutter is designed to ensure maximum machining reliability during complex 3D milling processes. The insert is constructed in a helically twisted structure that fits the seat constructed in a matching helical profile. This design provides secure insert positioning and fixation with anti-twist protection during machining. In addition, the strong, thick design of the insert helps to withstand machining impact preventing insert fracture.

The cutter body can accommodate either round LNMX-MJ inserts with 4mm, 5mm, or 6mm nose radius or LNMX-HJ inserts for high feed milling, making the cutter extremely effective for machining complex curved surfaces typical in die and mould industries.

The new cutter diameters include ø42mm, ø52mm, and ø63mm in popular shell mill bodies to accommodate the LNMX04 inserts. A total of three cutter bodies are added in this expansion.

CHECK OUT THESE OTHER ARTICLES

● Tungaloy’s Latest TetraForce-Cut Chipbreaker Provides Efficiency in Difficult Grooving

● Hwacheon on VMCs vs. HMCs

● EMO 2019: ANCA To Launch Latest Generation Of ToolRoom Software

● Cutting Tool Inserts To See Ballooning Sales

● Walter Expands Perform Product Range With New Milling Cutters With Corner Radius

● India & Spain Announce Plans For Rapid Rail Cooperation

● Sandvik Coromant: GC2220 Turning Insert

● Directing Investments In The Right Way

● Renishaw Demonstrates Additive Manufacturing Capabilities For Spinal Implants

● ISCAR Launches Chipformer For Finish Turning On Superalloys

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter

Walter Expands Perform Product Range With New Milling Cutters With Corner Radius

Walter has expanded its Perform product range with the launch of the new MC232 Perform solid carbide milling cutters. The MC232 milling cutter features a corner radius and reduced neck, allowing the user to better approach individual component geometries. It also improves the tool life of the milling cutter, as the edge stability is increased. The reduced neck in turn makes the milling cutter more flexible, as the user can use it with an even wider variety of cutting depths.

Other features of the Perform line have been adopted: the high level of cost efficiency for small and medium batch sizes, or Walter’s own WJ30ED grade, which provides a high level of wear resistance. ISO P materials are the primary application of the MC232 Perform, with ISO M and ISO K as secondary applications. The new milling cutters are likely to be of particular interest to job shops and manufacturers with frequently changing orders or quantities.

The Walter range in the MC232 Perform family now includes solid carbide cutters with or without a reduced neck and with or without a corner radius in a total of 126 dimensions, of 2–20mm in diameter. The milling cutters can be used for all typical milling applications (lateral milling, full slotting, pocket milling, helical plunging, ramping) and are suitable for a variety of materials and milling strategies.

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter

Sandvik Coromant Extends Advanced Insert Grades To Additional Milling Concepts

Following the successful introduction of its GC4330 and GC4340 steel milling grades, Sandvik Coromant is now extending the range of application for these advanced insert grades to additional milling concepts. The grades are now available for selection with the CoroMill 300 round-insert face and profile mill; the CoroMill 245 multi-purpose face milling cutter; and the CoroMill QD cutter, which is optimized for deep and narrow grooving and parting off.

GC4330 and GC4340, which feature a specially developed substrate, Inveio coating and enhanced post-treatment technology, allow users to enjoy substantially increased tool life and process security. The extension of these grades to additional Sandvik Coromant milling concepts brings their advantages to even more machine shops looking to optimize the milling of steel workpieces.

Among the many design attributes of GC4330 and GC4340 is the optimized Inveio coating. Inveio is the technical breakthrough of uni-directional crystal orientation in the alumina coating layer that gives inserts a new level of wear resistance and tool life. Furthermore, the substrate of the grades delivers highly controlled grain size distribution for more reliable and predictable insert behaviour.

GC4330 is a medium-hard grade for roughing to semi-finish face milling, while the GC4340 grade is for rough shoulder milling and groove milling. Both grades are also extended to the CoroMill 360 heavy-duty face mill, CoroMill 419 high-feed mill, and LPMH-PM plunge-cutter inserts. In addition, GC4330 is available for the CoroMill 365 high-security face mill, while GC4340 can be applied to the CoroMill 216 ball-nose end mill and CoroMill 415 small-diameter high-feed face mill.

FOLLOW US ON: LinkedIn, Facebook, Twitter

READ MORE IN OUR LATEST ISSUE!

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

Solid Ceramic Endmills For Machining Nickel-Based Superalloys

Following the steady increase in the processing of nickel-based high temperature superalloys (HTSA) such as various grades of Inconel, Incoloy, and Haynes, amongst others, in the aerospace industry, and the demand to decrease production costs, ISCAR has launched solid ceramic endmills that enable increasing the cutting speed by up to 50 times when compared to carbide tools, drastically saving machining hours and reducing production costs.

Available in two configurations—E3, with three flutes for shouldering applications, and E7, with seven flutes, feed mill style for rough applications—the new endmills can also be successfully applied to productive roughing of cast iron and graphite.

The solid ceramic endmills are produced from two ceramic grades: IS6, designed specifically for machining HTSA, and IS35, intended for cutting mainly cast iron and graphite. They are available in 6mm to 20mm diametres.

Check these articles out:

● Round Tool Concepts: Indexable, Solid or Both

● Reducing Energy & Lubricants In The Automotive Industry

● Kennametal Makes Hard Turning More Cost-Effective

● Schuler Develops System For Die Monitoring

● A Look at Walter’s Two-in-One Machining Concept

● Sumitomo Electrical Carbide: AC8000P Series Grades For Steel Turning

● Etihad Engineering Sets Up 3D printing Lab in Abu Dhabi, Receives Region’s First Approval to 3D Print Aircraft Parts

● GF Machining Solutions Form P 350 Die Sinking Electrical Discharge Machining

● The Metal Machining Versatility of Abrasive Waterjets

● Hexagon Enhances Post-Processed Simulation, Automation Features In ALPHACAM

FOLLOW US ON: LinkedIn, Facebook, Twitter

READ MORE IN OUR LATEST ISSUE!

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

- 1

- 2