ENTER THE WORLD OF OPTICAL METROLOGY

Measuring technology and software solutions from ZEISS provide perfect results in many sectors of industry — in automobile and aircraft construction, for example, where precision, quality and efficiency are essential success factors.

Optical metrology is the science and technology concerning measurements using light. These measurements may focus on the properties of light itself or other properties such as distance. Automation is taking over a major chunk of industrial processes worldwide and optical metrology is no exception. Companies are now catering to the needs of automation in processes of optical metrology as well. With a portfolio aligned with future growth areas like digitalisation, healthcare, and smart production, a strong brand like ZEISS is shaping the future of technology and constantly advancing the world of optics and related fields with its solutions.

Reliable Optical Measurements >> https://bit.ly/3p9Wl46

Did You Know:

Precise Measurement Technology Directly On The Shop Floor

Addressing CMM Challenges With Automated Quality Control

Operating in the Single-Digit Micron Range

3D Scanning Resolves Quality vs Cycle Time Conundrum

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

ZEISS Applies Artificial Intelligence to 3D X-ray Microscope Reconstruction Technologies

Two new reconstruction technologies that was introduced by ZEISS use Artificial Intelligence (AI) to improve data collection and analysis, and speed up decision-making. ZEISS DeepRecon Pro and ZEISS PhaseEvolve modules increase throughput by up to 10x while producing better than ever image quality. They’re designed for research fields including geosciences, pharmaceuticals, electronics, battery and engineering materials as well as for semiconductor failure analysis.

ZEISS PhaseEvolve is a post-processing reconstruction algorithm that enhances the image contrast by revealing the material contrast uniquely inherent to X-ray microscopy, often overprinted by phase effects in low-medium density samples or in high-resolution imaging.

The Advanced Reconstruction Toolkit (ART) on ZEISS Xradia 3D X-ray platforms gives researchers continuous access to the latest technologies for reconstruction, providing flexible workflow strategies as their imaging needs evolve. The toolbox is based on advancing reconstruction technologies beyond the typical “filtered back projection” or Feldkamp-Davis-Kress (FDK) algorithms. It enables acquisition and analysis with even fewer projections, reducing scan times by up to 10x, depending on the sample type and size, thus saving a considerable amount of time. These developments offer real benefits to professionals in academic R&D, high technology industry R&D, and industrial quality control & failure analysis laboratories as well as to university shared (core) facilities and mining/oil exploration (economic GEO) test labs.

ZEISS DeepRecon Pro

The DeepRecon AI-based technology is in two forms: ZEISS DeepRecon Pro and ZEISS DeepRecon Custom. Both modules provide improved image quality at high speed. DeepRecon Pro is a reconstruction technology that provides up to 10x higher throughput along with image quality benefits across a diverse set of sample types. It is applicable to unique samples as well as to semi-repetitive and repetitive workflows. Users can now train new machine learning network models themselves, working on-site with an easy-to-use interface.

ZEISS DeepRecon Custom is targeted specifically at repetitive workflow applications. ZEISS collaborates closely with users to develop custom-created network models that fit their repetitive application needs precisely.

ZEISS PhaseEvolve

The PhaseEvolve is a post-processing reconstruction algorithm that enhances the image contrast by revealing the material contrast uniquely inherent to X-ray microscopy, often overprinted by phase effects in low-medium density samples or in high-resolution imaging. This new module allows users to conduct more accurate quantitative analyses with improved contrast and segmentation of results.

Dr. Markus Ohl, Department of Earth Sciences, Utrecht University (The Netherlands) was one of the first users of ART. He says: “ZEISS DeepRecon Pro provides a straightforward, uncomplicated and powerful application of AI and deep neural network technology for enhancing X-ray tomography results without prior knowledge on deep learning technology.”

Both ZEISS DeepRecon Pro and ZEISS PhaseEvolve modules offer greatly improved image quality for many applications – typically 3D non-destructive sub-µm resolution imaging and 4D in situ studies. The traditional challenge of choosing between either image quality or sample throughput has been resolved with these new capabilities.

ZEISS ART with the optional DeepRecon and PhaseEvolve modules is available for immediate upgrade on existing ZEISS Xradia Versa and Context microscopes, enhancing the capability of installed systems as well as on new ZEISS Xradia X-ray microscopes.

Substantiating Quality With CMM

Here’s how ZEISS coordinate measuring machine has brought mechanical component manufacturer, Karl Reim Werkzeugbau GmbH production steps back under its own control.

Karl Reim Werkzeugbau GmbH is well known for the exceptional quality of its mechanical components. Located in Kirchheim unter Teck at the foot of the Swabian Jura, things were getting tight. The facility’s available space was occupied entirely by metalworking benches and machines.

“Every time we purchased a new machine, we had to take an old one out of service to make room for it,” says Stefan Reim, who, together with his brother Andreas and his father Dieter, is the third generation to run the company. In 2019 the company completed a facility expansion which provided additional floor space not only for production, but also for a metrology room.

Proven Quality

Karl Reim Werkzeugbau GmbH‘s components have always been of exceptional quality. “But we were unable to substantiate this with data,” says Andreas Reim.

With ZEISS CONTURA this is no longer an issue: the coordinate measuring machine clearly shows how large workpiece measurement deviations really are, and whether or not they lie within specified tolerances.

For some of Reim‘s individual parts and small-series production components, the tolerances are extremely narrow. This is the case with preset adapters, used by tooling machine operators to visually gauge their tools, which must be inspected in terms of their perpendicularity down to just a few arc seconds. Performing measurements with the CMM helps to further reduce the already very low rejection rate. And since the quality inspection is integrated early on in the manufacturing process, delivery times can be reduced by several days.

The plan to purchase a CMM first entered the minds of the company’s two managing directors two years ago. A customer had informed them that ZEISS was looking for pilot users to work closely with them to test the latest ZEISS CONTURA, to provide initial feedback and to help develop the newly constructed machine into an optimal solution. The collaboration proved beneficial for both parties: Andreas and Stefan Reim provided ZEISS with valuable feedback about the device, and ZEISS in turn ensured that Reim received exceptional levels of support in the months following commissioning of the machine.

Small Space Requirements Paired With a Large Measuring Volume

The fifth generation of ZEISS CONTURA machines was made for operations like Reim Werkzeugbau. The machine was redesigned from the ground up and is now so compact that it provides a 30 percent larger measurement volume when installed in an area of the same size and with a noticeably reduced device height. The managing directors at Reim were given an introduction to the new machine over the course of three days. “This device offers so many possibilities — for first-time users this is astonishing at first,” says Andreas Reim. But thanks to the on-site training provided by ZEISS, the two CMM newcomers were able to quickly learn how to operate the device.

To continue reading this article, head on over to our Ebook!

For other exclusive articles, visit www.equipment-news.com.

Check these articles out:

Overcoming Challenges In Production With Multisensor Measuring Machines

HMI Introduces New CMM Solution For Precise Inspection Of Delicate Electronic Parts

Software Increases Process Reliability

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter

From Users for Users

Here’s how one company was able to scan large and very heavy parts from all four sides and from above, without having to laboriously move the piece. Article by ZEISS.

When a robot grasps a cylinder block weighing 50 kilos and approaches a saw or milling cutter, any vibration or sliding motion must be avoided. But deviations from target production data make it difficult for the robots to grasp. August Mössner GmbH & Co. KG, which manufactures specialised machinery for the foundry and aluminium industries along with saws for the widest possible variety of materials as well as equipment for the dismantling of nuclear power stations, has found a solution for this problem. As well as tailor-made manipulators for robots manufactured with the aid of the ZEISS T SCAN, the programming of the equipment is optimised with flexible laser scanning.

Christian Kunz (right) and Christian Haase inspect the grippers of a robot. They are to hold heavy motor castings to the processing stations later on, which protrude from the wall on the right.

The two robot arms rigidly stretch their necks into the air, their movements appear frozen. One of them holds a cylinder block in suspension, weighing at least 50 kilos. Only in a few weeks’ time, when the entire plant has been completed, will they start moving and saw off disturbing feeder and sprue systems and mill off casting flashes on engine blocks coming from a foundry. To do this, they heave the parts to saws and milling machines that protrude from the wall and look like giant dentist drills.

Here at August Mössner in Eschach is not where they will be put to work, however, but rather at engine plants of well-known automobile manufacturers. The processing stations are designed and put into trial operation at August Mössner, which has a reputation in the automotive industry for delivering automated production lines with dozens of robots on schedule and perfectly functional.

Deviations of Several Millimetres

Christian Kunz is the Head of Robotics, R&D, at August Mössner. His team plays an important role when it comes to deviations. The 20 employees of his robotics, research and development department are responsible for planning the precise, safe and efficient operation of the processing lines.

But the devil is in the details. One of these details are the contour parts with which the robots grip the cylinder block. They are as small as a hockey puck, but must be able to grip the casting precisely and hold it in position during processing, against the forces that occur. For this purpose, the contour parts have recesses that fit exactly over the bulges of the castings. However, this is initially not the case.

Kunz holds a contour part to the rough casting of a gearbox-housing, at the point where the robot is later to pick up the component. But no matter how the mechatronic engineer turns and tilts the fitting, the parts do not fit together. “When car manufacturers send us castings, they often deviate from the target design by a few millimetres,” explains Kunz.

This is no wonder, since most of them are so-called start-up parts for new engine types.

The tolerances are still large when series production starts and are not shown in the CAD models of the castings. Kunz and his team have found a solution in which ZEISS T-SCAN is of central importance. Using a hand-held laser scanner, the engineers measure the surface contour of the casting—for example, of an engine block or a transmission housing—and compare the data set generated by this with the target CAD data supplied by the car manufacturer. On the one hand, this serves to document the actual state and on the other hand, the measurement is the basis for adapting the contour parts to the casting and for subsequent programming of the robot. In this way, the engineers can quickly see where there are deviations and can immediately initiate reworking of the contour parts. The contour part is reworked by hand, then scanned and can thus be documented and converted into CAD data.

To continue reading this article, head on over to our Ebook!

For other exclusive articles, visit www.equipment-news.com.

Check these articles out:

The Global Aluminium Castings Market To Grow By US$32.1 Million Despite The Pandemic

Sandvik Coromant Joins Forces With Microsoft To Shape The Future Of Manufacturing

Round-the-Clock Environment Disinfection With SESTO Autonomous Mobile Disinfectant Robot

5G Integration In IIoT Systems Accelerates Industry 4.0 In The Wake Of Pandemic

Six Factors That Have Changed Bending Automation

Automation Trends in Metalworking

3D Technologies: Not Out Of Our League

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter

ZEISS Partners Microsoft To Accelerate Cloud Solutions For Efficient Manufacturing

ZEISS Group and Microsoft Corp. has announced a multi-year strategic partnership to accelerate ZEISS’ transformation into a digital services provider that is embracing a cloud-first approach. By standardising its equipment and processes on Microsoft Azure as its preferred cloud platform, ZEISS will be able to provide its customers with enhanced digital experiences, address changing market needs more quickly and increase its productivity.

Leveraging Azure high-performance compute, AI, and IoT services, ZEISS will work with Microsoft to provide original equipment manufacturers (OEMs) with new quality management solutions, enable microchip manufacturers to build more powerful, energy-efficient microchips and deliver new digital healthcare solutions for improved clinical workflows, enhanced treatments, and device maintenance. Furthermore, ZEISS will create a seamless experience for its customers through one digital platform and manage all digital ZEISS products through one cloud-native platform to enhance continuous and agile product development.

Connected quality platform drives industrial efficiency

Initially, ZEISS will enable its solutions in the Industrial Quality & Research segment to be run on a connected quality platform built on Azure, allowing direct integration into the customer’s production process. The platform will help gain business insights and foster collaboration across domains, assets and processes that have traditionally been managed in siloed, proprietary systems.

ZEISS provides metrology and quality assurance solutions delivering meaningful information on parts dimensions, component behavior and defect detection. Real-time and large-scale analysis of data that is collected at all stages of the manufacturing process is key to efficient and effective quality assurance, tightly integrated with today’s and tomorrow’s IoT-enabled production processes.

Quality is also a key objective of a new ZEISS audit trail solution, initially focused on highly regulated manufacturing industries, such as medical technology which is particularly sensitive to quality assurance. The solution will allow customers to identify root causes and react quickly on quality issues to reduce down-time and keep productivity up. The software will allow customers to track, trace, visualize and analyze process and product data with the help of Azure AI services to identify failure root causes more quickly.

Data-driven healthcare solutions improve patient care

ZEISS Medical Technology provides comprehensive solutions for ophthalmic professionals and microsurgeons, consisting of devices, implants, consumables and services. Through the partnership, ZEISS will connect its medical technology to Microsoft’s cloud and leverage Azure AI and IoT technologies for new digital services such as improved clinical workflows, enhanced treatments, and device maintenance in a secure environment that enables compliance with regulatory requirements in the health industry. These solutions will help improve the quality of life of patients and drive progress, efficiency and access to healthcare.

For other exclusive articles, visit www.equipment-news.com.

Check these articles out:

A Look At How 3D Measurement Technology Helps Reduces Total Lead Time

FARO Offers New Capabilities With CAM2 2020 Software

How Can Portable CMMs Help Improve Machine Shop Workflow?

Gaining A Competitive Edge With Additive Manufacturing

Hexagon Enhances Portfolio For CMM With Swift-Fix Chucks

Large-Scale Metrology For Oil Industry

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter

Software Increases Process Reliability

Here’s how a quality data management software has helped Metabowerke GmbH to optimize its measuring and manufacturing processes. Article by ZEISS.

If employees at Metabowerke GmbH, a manufacturer of professional power tools and accessories, find a piece of chocolate at their workstations on the first workday of the new month, then everyone knows that the previous month was a profitable one. The chocolate is one way that management shows its appreciation, and this is hardly a one-off occurrence. Employees think so highly of their employer that, as the result of an employee survey, Metabo was named “Best Employer” amongst mid-sized companies in 2014 by the German magazine Focus.

Achim Schmid, Quality Coordinator in the Housing Technology Center, shares his colleagues’ high opinion of Metabo. For him, the approximately 1,100 employees in Nurtingen are always ready to give 110 percent because company management acknowledges everyone’s contributions.

“We know that at Metabo, our opinions and know-how matter,” says Schmid. The company’s flat hierarchies make sure that everyone is heard and can actively contribute.

There is an interdepartmental mindset at Metabo that encourages employees to work with their colleagues from different areas. This approach played a key role in the company’s decision to purchase ZEISS PiWeb quality data management software. After Control 2015, an international trade fair for quality assurance solutions held in Germany, Schmid was personally “more than convinced that Metabo would benefit from using ZEISS software. But first I wanted to make sure everyone else was on board.”

The software was presented to employees and discussions were held, some of which were attended by ZEISS representatives. The end result: Metabo ultimately decided to invest in ZEISS PiWeb sbs in the middle of 2016, and has been using this software in the Housing Manufacturing department at their site since December.

Wireless Systems Instead of Cable Spaghetti

When attending the trade event Control 2015, what initially impressed Schmid about ZEISS PiWeb was the possibility of transferring manually captured measuring and inspection data directly to the system via a wireless connection.

“I really liked that you could easily integrate manual measuring tools,” says Schmid, who has been working at Metabo as quality coordinator for almost 31 years. The feature was “ideal” because various manual measuring tools are in use at the measuring stations in the Housing Manufacturing area. Prior to the introduction of ZEISS PiWeb, these systems were connected via cables, which not only limit employees’ mobility but also broke quite frequently, making it impossible to transfer the data to the system. The technology was not very reliable, and uptime was limited because the measurement plan had to be processed at one go. This meant that captured data could not be saved in between measurements.

“But now, these problems are a thing of the past thanks to ZEISS PiWeb,” says Schmid. For example, if an employee is measuring the gearbox housing of a flat-head angle grinder, they just need to open the corresponding measurement plan in the ZEISS software. The employee moves the cursor to the appropriate field in the table comprising a total of 17 characteristics, which must be measured by hand. With the push of a button, the employee transfers these data from the manual measuring tool to the system. If the value is within the stipulated tolerance, then a green dot appears immediately. A red dot indicates that the workpiece does not meet the quality requirements for this characteristic. It used to be the case that the employee would have to change software and then search for the corresponding data set in the statistics solution. Now, they can view the measurement values for the previous 500 measurements just by using the report templates in ZEISS PiWeb.

“This way, our team sees immediately if this is an outlier or if there is a trend towards exceeded tolerances,” says Schmid. This knowledge enables Schmid and his colleagues to steer the production process more quickly than before.

To continue reading this article, head on over to our Ebook!

For other exclusive articles, visit www.equipment-news.com.

Check these articles out:

Ensuring That A Propeller Keeps A Heart Beating

ZEISS Completes GOM Acquisition

Precision For Guaranteed Stability Using 3D Scanners

TRUMPF And Fraunhofer IPA Research Alliance Ramps Up AI For Industrial Use

Profound Machinery Benefits Of A Multi-disciplinary Design

A Secret Weapon For Aerospace, Automotive Quality Control Managers

ZEISS and Senorics Establish Partnership In Sensor Technology

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter

CMM With Mass Technology: Versatility In Focus

The demand for measurement tasks in which tactile and optical sensors are jointly used is set to rise more and more in the future. Here’s a technology that saves time and operating costs without compromising on reliable, precise measurement results. Article by ZEISS.

When it comes to maximum precision, coordinate measuring machines (CMMs) are an indispensable tool in industrial applications. To date, they have mainly been used for tactile measurement. In recent years, the need for and use of optical sensors is becoming increasingly significant. There are many reasons for this: the technical advancements being experienced in many sectors require increasingly complex parts; digitalisation and Industry 4.0 are changing manufacturing processes and thus also quality assurance; and customers have higher quality and efficiency demands, in general, nowadays. Many companies are therefore expressing the need for an all-round solution, that is, tactile and optical measurement on a CMM.

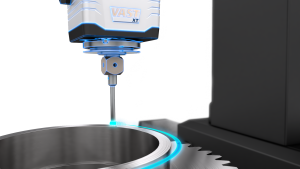

One example is the ZEISS CONTURA. Already in its fifth generation, ZEISS CONTURA is equipped with mass technology (multi-application sensor system) as standard, enabling tactile and optical measurement on a single machine. The multisensor platform means it is compatible with a variety of sensors from the ZEISS portfolio: sensors on the continuous articulating unit, star styluses or long styluses, optical or tactile, and scanning or with single point measurement. Thanks to the mass technology from ZEISS, the user acquires maximum flexibility.

Simple Sensor Switch

With ZEISS mass technology, when the sensors are operated on the continuous articulating unit, they are switched automatically. This applies to all optical sensors as well as the ZEISS VAST XXT and XDT tactile sensors.

During the sensor switch, the continuous articulating unit aligns itself in a 90 deg position, with the sensor pointing downwards. It then moves to a free place in the sensor magazine, which is usually attached to the reverse end of the measuring stage, pushes the safety flap back, moves downwards into a groove, and releases the magnetic locking mechanism in order to unlock the sensor. The new sensor is picked up in a similar way: the continuous articulating unit moves backwards and opens the safety flap, moves downwards and picks up the sensor magnetically. On the plate holding the sensor, there are three cylinder-shaped rollers which ensure that the counterpart is precisely positioned on the sensor.

Therefore, even after frequent switches, the sensor is reproducibly situated at the correct point. The measurement uncertainty is not increased by any significant extent due to the sensor bracket. Users do not need to worry that the accuracy may get out of hand if the sensor is switched repeatedly. Due to the high repetition accuracy during the sensor switch, it is not necessary to recalibrate the sensor after the switch has been carried out. Since the automatic exchange itself takes only a few seconds, ZEISS mass technology means an enormous boost in productivity – and thus time and cost savings.

The continuous articulating unit itself, as well as tactile probes from the ZEISS VAST XT gold series, are attached to the ZEISS CONTURA by means of a dovetail mechanism. This is a groove which the counterpart on the sensor or on the continuous articulating unit is pushed into and which, due to its shape and precise processing, does not allow any leeway whatsoever. Handling is easy too: the measuring technician loosens a screw mechanism and pulls the sensor or the continuous articulating unit out of the groove and inserts the new sensor. The sensor switch is completed within seconds. However, a repeated calibration is crucial during a sensor switch and is especially useful when using an active tactile sensor such as ZEISS VAST XT gold, which offers high measuring accuracy, short measurement times and long stylus lengths. All other sensors—passive, tactile as well as optical—are ideally operated on the continuous articulating unit—with all the advantages of the automatic sensor switch of ZEISS mass technology.

Optical Measuring Procedures

Optical measuring procedures are particularly interesting in parts with complex shapes if the user is required to record the surface quickly. This is useful in production in order to safeguard the quality of process steps, such as casting metal blanks or after grinding, in order to obtain a quick comparison between the current and target values of the CAD file. Optical sensors are also ideal for reverse engineering, that is, in order to generate CAD data from a prototype. Optical measurement procedures are often faster than tactile procedures and nonetheless sufficiently accurate. For sensitive parts which may not be touched, there is no alternative to optical sensors.

Various optical sensors can be more suitable depending on the application:

- Chromatic-confocal white light sensor: This type of sensor is used in the area of application of workpieces with sensitive, soft, reflective or low-contrast surfaces. It records the surface of sensitive parts which may not be touched—where tactile styluses are obviously excluded. This sensor even detects transparent painted surfaces above underlying metallic layers and is suitable for transparent layers with various refractive indices. For this purpose, the sensor uses white light, which includes all wavelengths of the visible spectrum. Even strongly reflective surfaces such as glossy metal parts either in automotive and engineering or knee implants do not need to be sprayed with a contrast medium, which other optical measurement methods usually require.

ZEISS offers such a pioneering chromatic confocal white light sensor: DotScan. The sensor can be rotated and swiveled in 2.5 deg steps so that it is always optimally aligned towards the surface. In conjunction with the optional rotary stage, it is suited, for example, to the quality control of parts with complex shapes as well as glass surfaces.

- Triangulation laser: suitable for the fast recording and inspection of freeform surfaces such as those required by casting tools or castings, bent sheets or plastic covers also require non-tactile measurement. The sensor moves above the part at a distance of a few centimetres and projects a line with laser light, which is thrown back from the surface into a sensor chip. Based on the angle, the sensor determines the distance from the part and therefore its surface shape. Each time the light is projected, the sensor determines hundreds of points in a line.

The maximum possible number of points with ZEISS LineScan is 700,000 measurement points per second—the number of rough points which are then calculated to provide actual measurement points in the software. Thus, point clouds which fully record the complex surfaces of even larger parts can be created in just a few minutes. Based on the point cloud, the ZEISS CALYPSO software calculates a chromatic representation using the CAD target data record as a comparison.

- 2D camera sensor: for very small or two-dimensional parts such as circuit boards or flat parts made of sheet metal that cannot be measured using contact means because it may result in deformation of their surfaces, the ZEISS ViScan 2D rotatable camera sensor is the ideal solution. It is capable of recording height-related information, thanks to the Autofocus function, as well as features various objective lenses, enabling increased flexibility in the working distance, area being recorded and accuracy.

To continue reading this article, head on over to our Ebook!

For other exclusive articles, visit www.equipment-news.com.

Check these articles out:

Smart Sensors Are Bringing About A Paradigm Shift In Production

Zeiss: O-Inspect Multi-Sensor Measuring Machine

Integrated Quality Control Of Turbine Blades In An Automated Production Cell

Benefits Of Introducing An Optical Measurement Method With Fringe Projection

Driving the Next Industrial Revolution

3D Scanning Prevents Production Downtimes

Hexagon Advanced Positioning System For Automated 3D Optical Measurement

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

High-precision Layer Work

Find out how MBFZ toolcraft ensures holistic quality control and precision in additive manufacturing. Article by ZEISS

Frederik Mack, Materials Engineer at toolcraft, examines a test specimen under the ZEISS Axio Imager microscope, which he sawed out of a 3D-printed part and ground.

Additive manufacturing is an uncharted territory for many companies, but not for MBFZ toolcraft GmbH. The company in Georgensgmünd, Southern Germany, manufactures high-end precision parts for the aerospace, automotive, medical technology and semiconductor industries, among others, and since 2011 also parts using 3D printing. The young established production technology is a challenge for quality assurance. Toolcraft is mastering this challenge with ZEISS 3D ManuFACT, the only solution on the market for continuous quality assurance in additive manufacturing.

Heat, noise, the smell of oil: They belong to industrial manufacturing like Yin to Yang. Yet this is quite different in the glass hall at toolcraft in Georgensgmünd. Anyone who has access to the area with their employee ID card hears nothing. They smell nothing either. There are few reminders of factory life as we have known it for a hundred years, because parts are not manufactured the way they have been for a hundred years. Instead of peeling the mold out of cast or forged metal blocks by drilling, milling and turning, additive manufacturing comes at the process from the other way.

Through small windows on the twelve 3D printing machines at toolcraft, you can watch glistening laser beams dancing over a wafer-thin layer of metal powder. Where the spot of light hits, the powder melts in a flash and immediately solidifies again, followed by the next layer. Thousands of hair-thin layers are used in 3D laser melting to create „impossible“ components that could never be produced with traditional subtractive manufacturing. Whereas ten years ago only prototypes and design studies were produced by using additive manufacturing, manufacturers of aircraft turbines, racing cars or medical equipment are increasingly incorporating them directly into their series products.

Challenges for Quality Assurance

As always, when a new technology emerges in a market, there are always questions. One of them is quality assurance. Jens Heyder points to a monitor that shows two images taken with the ZEISS Axio Imager light microscope at 50x magnification. On the left you can see a section of a good component. There are no large defects visible, only small pores. The material has an even, homogeneous structure. On the right, there is a cross cut shown, in which blowholes and welding defects are present. The construction process here was not optimal, which is why errors occurred during solidification of the melt.

“Crack formation could occur under high loads,” warned Heyder, who has been working as a material engineer in toolcraft’s materials laboratory for three years. Together with his colleagues, he checks the grain size distribution of the metal powder used. They help to optimize the manufacturing process in such a way that no defects occur in the part during melting and solidification.

However, the materials laboratory is only one component in the seamless quality assurance at toolcraft. Each process step is followed by a test: when a part comes out of the printer, after heat treatment and finally after milling into the final form, before the part is sent to the customer. Not every part is inspected. Random samples are taken according to customer requirements where typical parts only undergo a final inspection. For more demanding customer requirements, such as the aviation industry, 100 percent inspection and precision is required.

But one thing is for sure: when a part is inspected, it is done on a machine with the ZEISS logo. These can be found in several places in measuring rooms and in production at the company: two microscopes (ZEISS Axio Imager and ZEISS Axio Zoom.V16), several coordinate measuring machines (two ZEISS ACCURA, one ZEISS CONTURA and one ZEISS DuraMax) as well as an optical 3D scanner. Although the latter bears the GOM logo, the company also belongs to the ZEISS family since spring 2019.

To continue reading this article, head on over to our Ebook!

For other exclusive articles, visit www.equipment-news.com.

Check these articles out:

Intelligent Machine Software For Improved Precision Machining

Hexagon And Ericsson Host Joint Webinar On The Role Of 5G In Industry 4.0

The AMable Project Promotes Flexible AM Solutions To Fight The Coronavirus

Driving the Next Industrial Revolution

NAP 2020 Drives Malaysia’s Automotive Sector

A Look At How 3D Measurement Technology Helps Reduces Total Lead Time

Driving For A Better Tomorrow Hexagon Manufacturing Intelligence

Large-Scale Metrology For Oil Industry Production

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter

Quality Assurance Brings New Confidence

Here is why it is critical to incorporate advanced quality inspection equipment into your manufacturing processes. Article by ZEISS.

Figure 3: VAST XXT sensor measuring magnesium housing assembly for passenger door.

The manufacturing industry has changed dramatically in the last 40 years. Jamco Aerospace Inc. recognised these changes and realised how critical it is to incorporate advanced quality inspection equipment into their manufacturing processes to stay competitive. They use two scanning CMMs (coordinate measuring machines) from Carl Zeiss Industrial Metrology (IMT) to ensure the precision of these processes every step of the way.

Jamco Aerospace is a manufacturer of complex, structural components typically used in the aerospace industry. Ninety-five percent of their orders come from the aerospace industry, with the remaining five percent coming from the ground transportation industry. The company is a full-service machining and airframe sub-assembly facility. Some of their larger customers include Northrop Grumman, Boeing, Spirit AeroSystems, and the US government.

READ: The E-Mobility Roadmap: Speeding Up Tool Development With A High-Accuracy CMM

In 2006 Jamco decided they needed more efficient quality inspection equipment to stay competitive in their industry and to comply with their recent ISO 9001/AS 9100, Rev. B certifications that require significant process documentation. Their touch-trigger CMM and manual gauges were no longer effective and the CMM’s software had also presented some programming challenges. They needed a new CMM that was comparable in size to their previous CMM but with better measuring technology.

“I have been involved in this business for over 40 years and the manufacturing base in the US has grown increasingly smaller and more competitive,” says Dr. Jack Lee, CEO of Jamco. “The scanning inspection technology is spreading fast and I believe the key is to improve quality throughout the entire manufacturing process, otherwise the final inspection is completely worthless.”

Technical Specification Fulfilled

Ronald Lee measuring main landing gear rib on the MMZ 20/50/15.

After an in-depth review, Jamco decided that a Carl Zeiss CONTURA G2 10/21/6 VAST XXT RDS with scanning technology was the best fit for their inspections. The CONTURA G2 10/21/6 is robust and the right size for their parts. The VAST XXT RDS articulating probe is designed for measuring small features and lots of angles, and can reach 20,736 positions in 2.5 degree increments. The scanning technology allows them to get much more information in a shorter amount of time than with their previous touch-trigger CMM, a feature that brings down manufacturing costs by improving efficiency.

READ: Driving the Next Industrial Revolution

Typical parts for Jamco are structural bulkheads or fittings used in aircraft which they measure on the CONTURA G2 for in-process and final inspection. Parts are inspected on the CMM after any initial finishing processes, before moving on to turning or milling processes followed by a second inspection. A final inspection is done after all processes or assembly are completed. The increased efficiency resulted in more orders over the years although most of their parts require 100 percent inspection. As the number of parts and orders grew, the company knew it would need an additional CMM.

They liked the CONTURA system with the VAST XXT RDS articulating probe but wanted a larger machine to more efficiently handle larger aerospace parts such as bulkheads, longerons, ribs, webs and frames, while keeping the same CALYPSO software and ZEISS quality. In 2011 they purchased a large gantry CMM, an MMZ 20/50/15 which could not only measure larger parts, but also large lot sizes of smaller parts.

READ: Making the Most of CMM Assets

Jamco appreciates the simplicity and user-friendliness of CALYPSO software. “Once you know what to look for it is pretty straight forward,” says Ronald Lee, Quality Control Manager at Jamco. “If an operator is unsure how to set up a part, the software shows multiple part views to make the process easier. And programming from CAD models with CALYPSO is a lot easier due to the integrated assistant that helps you select the measuring references so there is no difficult code or text editing. This allows you to spend more time measuring than programming, unlike with our previous metrology software.”

Increased Efficiency

The ZEISS systems have helped Jamco gain more customers with their improved quality inspection accuracy and efficiency. The CMMs also allow them reach their targeted tolerances that are all within 5 ten-thousandths of an inch. Their touch-trigger CMM collected about 100 points in 2 to 3 hours while the ZEISS scanning CMMs gather about 1000 points in just 1 to 2 minutes. Jamco currently measures approximately 30 parts a day. Typical parts are around 12 inches long and have a number of critical features requiring 30- 40 minute inspection programs. Efficiency is also increased because operators can multi-task while inspections are running. For larger orders of about 40 parts, they like to use the AutoRun feature so entire lots of parts can be inspected automatically.

READ: Achieving Perfect Gaps And Joints

The ZEISS systems have given Jamco the confidence in their ability to do more inspections and projects, and to measure bigger parts. The ZEISS MMZ machine effectively handles the larger parts, but it also inspects a pallet of smaller parts at once instead of having to do a series of measurements. “Quality assurance throughout all of our manufacturing processes has brought new confidence to us and our customers,” states Dr. Lee.

For other exclusive articles, visit www.equipment-news.com.

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter