Mastercam Announces New Add-On for Additive Manufacturing

Mastercam announced a new Add-On product, Mastercam APlus by CAMufacturing Solutions, designed for additive manufacturing. APlus can be used with Mastercam Mill, Lathe, or Router licenses.

Mastercam, announced a new Add-On product, Mastercam APlus® by CAMufacturing Solutions, designed for additive manufacturing. APlus can be used with Mastercam Mill, Lathe, or Router licenses.

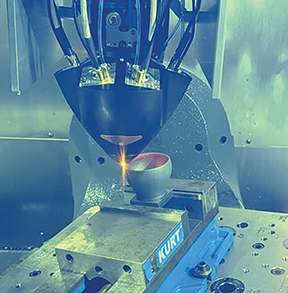

Using the same interface Mastercam users are familiar with, APlus customers can program, backplot, and simulate their 3D printing scenarios just like they would with traditional toolpaths in Mastercam. APlus uses Direct Energy Deposition (DED) and has toolpaths developed specifically to handle any geometry in Additive Manufacturing (AM), as well as features and utilities designed to remove uncertainty out of the process and to improve efficiency.

Hybrid manufacturing provides users with the versatility to build parts from scratch, add features to an existing part, or to repair a worn or damaged part. APlus integrates seamlessly with Mastercam to allow users to generate Additive Manufacturing toolpaths, as well as visualise the additive and machining outcome.

Kenneth Fortier, Technical Product Manager, Mastercam says “APlus brings Additive Manufacturing to the Mastercam user in a form that is consistent with the workflow used for over 40 years. Direct Energy Deposition is making its way into many machine shops and being able to program hybrid machines or dedicated additive machines using Mastercam makes the transition seamless. With the hybrid process of alternating adding material and milling allows parts with internally machined features to be created that would have been impossible without additive.”

Since Additive Manufacturing is not simply reversing machining toolpaths, all features and toolpaths are designed and developed to ensure users experience efficient and practical results for the additive and hybrid manufacturing process. A great application for using APlus is for blade repairs where the tips of individual blades are showing wear.

To repair the part, the user machines off the worn tips using a suitable toolpath in Mastercam. Using APlus, you can 3D print or deposit material onto the machined surfaces to near net shape.

Finally, you machine the printed sections to the desired specifications. This process can dramatically lower costs when compared to buying or machining a new blade, or even stocking spare parts.

Related Stories:

3D Smart Solutions Largest 3D factory In Vietnam Commences Operation

EMO 2023: Trumpf Opens Up New Applications And Reduces Waste

In-Vision Aids Revolutionary Sub-Micron 3D-Printing Development

Manufacturing Companies Convinced Of 3D Printing, But Struggle To Get It Right

3D Printing Is A More Efficient Way To Make Aircraft Parts

First Successful Operation With Custom 3D-Printed Titanium Lower Jaw

3D Printing: Revolutionising Robotics & Automation Companies in Singapore

3D Printing Can Strengthen America’s Medical Supply Chain

3D Systems to Accelerate High Volume Additive Manufacturing with Acquisition of dp polar GmbH

3D Printed Human Cornea Developed Clinicians And Scientists In India

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

CONNECT WITH US: LinkedIn, Facebook, Twitter

Letter to the Editor

Do you have an opinion about this story? Do you have some thoughts you’d like to share with our readers? APMEN News would love to hear from you!

Email your letter to the Editorial Team at [email protected]