Intelligent Machine Software For Improved Machining

Industry 4.0 is more than just a slogan if a manufacturer succeeds in generating a specific benefit for the end user from technological developments. Contributed by Wenzel

Various projects can be created from a framework through implementing Wenzel 4.0—a machine interface—to meet a company’s need for highly specific requirements with directly measurable advantages. For example, the software can be used for 3D printing to react more specifically to customer requirements when facing specific materials or parts.

Increasing Throughput And Flexibility

Digital workstations are able to be installed, which provides employees with all relevant information of production orders, paperless and directly to the workstation on the shop floor. This increases throughput and flexibility. By implementing new and very user-friendly software solutions in customer service, it is possible to react to customer enquiries even faster and more efficiently.

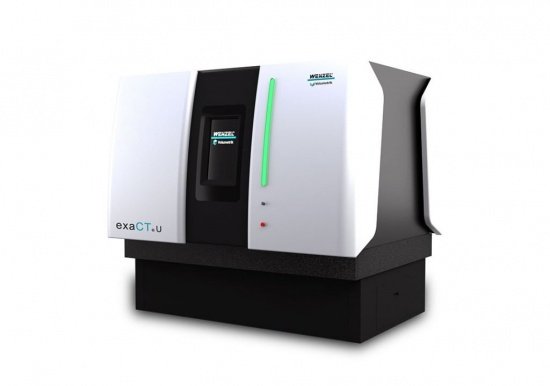

The machine interface solution is equipped with a touch panel, which is optimised with various features to guarantee a convenient operation of coordinate and gear measuring machines. The touch panel allows machine and measurement software control directly at the machine, whilst maintaining an optimal view of the machine and part.

Collecting And Analysing Information

Users are also able to easily collect, analyse, and present information regarding the application of the machine through the intelligent machine interface (IMI) which consists of three modules. With the implementation of the mi-WLINK, which is a software solution, it can collect and process all information from the measuring machine’s environment. The environment information includes data regarding the ambient temperature, the humidity and the historical performance of the measuring machine, but also any ongoing problems or wear to critical parts are recorded.

For this purpose, integrated sensors as well as information from the controller are used. In addition, warnings and status reports from the application software can be easily integrated. Information about currently running measuring programs or more specific error messages can be processed in this way. This collected information is then processed in a standardised manner for each individual measuring machine and can be evaluated in various scenarios.

Access Machine Information Anywhere

If manufacturers need their machines to be set up in a single measuring room, they have the option of the mi-Wguard. If manufacturers need their machinery to be connected anywhere in the world they are being used, the global mi-Wguard solution would be more suited for their needs. The data can also be transferred to a secure data area, should they consent to it. This enables a new quality of cooperation between Wenzel service technicians and the manufacturer, including the possibility to conclude a maintenance contract with predictive maintenance.

Visual presentation is provided by an updated software solution—the mi-Wpanel—which allows manufacturers to be interactively informed about the condition of all connected measuring machines. Depending on the chosen scenario, the current condition of all measuring machines can be viewed at a glance.

Detailed information can then be retrieved with the help a double-click at any time. This is possible in the workplace as well as externally with the use of mobile devices such smartphones or tablets. To facilitate the monitoring of an entire measuring room (local scenario) or of all machines of a customer worldwide (global customer scenario), manufacturers can rely on the mi-Wpanel.

Collecting data and processing it in an expedient manner is an important step to further improve efficient use of measuring machines, and digital transformation projects enable manufacturers to achieve this.

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter