Flexible Sawing Solution for Additively Manufactured Parts

Flexible Sawing Solution for Additively Manufactured Parts

The growing additive manufacturing industry has demanded new requirements in the sawing process. Article by Behringer.

Additive manufacturing, or 3D printing, has become more and more important in nearly all industries. 3D printing is a ground-breaking and innovative technology that has the potential to bring intermediate changes in manufacturing, society and business. As a crucial medium connecting the virtual and actual world, 3D printing enables the transformation of digital files into tangible objects.

According to market analyst firm Inkwood Research, the global 3D printing market is expected to register a compound annual growth rate (CAGR) of 17 percent from 2019 to 2027 and reach a value of US$ 44.39 billion at the end of the forecast period. While North America is the dominating region, Asia Pacific is the fastest growing market for 3D printing.

One important and growing segment of the 3D printing market is the metal additive manufacturing industry. Metal additive manufacturing is increasingly becoming popular among automobile manufacturers across the world. This is because additive manufacturing helps automakers to build stronger and lighter parts within a short period. The technology is now widely adopted by various Formula 1 teams, including Scuderia Ferrari, Williams Martini Racing, and Mercedes-AMG Petronas to produce lighter components such as rear wings, gearbox assemblies, and bodywork to improve the performance of their cars. Many supercar manufacturers are also adopting metal additive manufacturing to reduce overall cost, lead time, and weight. The rising adoption of metal additive manufacturing in the automobile industry is expected to fuel the growth of the market. According to a report by market analyst Technavio, the metal additive manufacturing industry is expected to grow by $4.42 billion during 2020–2024.

High Sawing Precision

The additive manufacturing processes make it possible to produce simple as well as complex parts in different materials. 3D printing offers many advantages, such as higher design flexibility, and the individualization of the products (a batch size of one). From a process perspective, the additively manufactured parts are printed on a base plate via a supporting structure. To use and process the 3D printed parts, they have to be detached from the base plate.

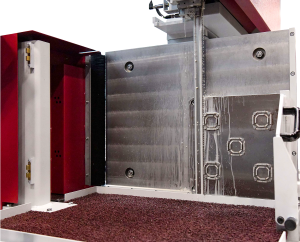

To address this trend, and in line with the 100th anniversary of Behringer, the company expanded its product portfolio with the release of its 3D-Series of sawing machines. Available in two models—the two models HBE320-523 3D and LPS-T 3D—the high-performance sawing machines were developed for cutting additively manufactured parts in different sizes and shapes.

To continue reading this article, head on over to our Ebook!

For other exclusive articles, visit www.equipment-news.com.

Check these articles out:

Sandvik Coromant Joins Forces With Microsoft To Shape The Future Of Manufacturing

CHIRON Launches First 3D Metal Printer

New Chucks For Standardised Processes

Boeing Partners With Oerlikon To Increase Adoption Of 3D Printing

DKSH and HP Discuss Industrial Transformation Through 3D Printing

Renishaw Sees Continued Demand for Accuracy and Precision Driving Growth

Auto Sector Faces Biggest Existential Crisis Since 2007-09

Sheet Metal Fabricator Cuts Inspection Time by 60%

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter