A Clear Vision For Industrial IoT

Syed Shah caught up with Scott Summerville, President, Microscan, on machine vision and the implication of the Industrial Internet of Things (IIoT) for his company and the manufacturing.

What are your thoughts on the increasing relevance of machine vision in manufacturing?

There is a lot more capability to create demand and solve customer issues when you are talking about intelligent sensing devices like machine vision smart cameras with fully-featured software. These tools are what I would categorize as advanced manufacturing, and I would consider PLC-driven process machinery as a more base-level automation. There are a lot of companies that install automation systems to achieve acceptable product quality levels, or simply because human interaction is no longer sufficient to do things like building cars and making steel. That being said, machine vision technology is still highly discretionary. It is not necessarily a requirement, because you could potentially accomplish your quality goals through manual inspection (although it is not as tireless or accurate).The same goes for barcode reading for traceability – it is highly efficient, but it is not necessarily mandatory. It is incumbent upon us as the manufacturing supplier to help the customer justify ROI and demonstrate the benefits of our automation technology.

Could you explain a little more about the difference between ‘mandatory’ and ‘discretionary’?

There are some regulatory requirements, particularly in the life sciences, that are beginning to require unique device identification for items like medical devices and pharmaceuticals. These requirements are mandatory and will soon be applied as a global standard. The use of machine vision and barcode reading for traceability is largely discretionary. There is enough impetus to put in traceability systems to ensure that the products manufactured reach their intended destination and they can be tracked and traced directly to the consumer in the event that there is a recall. This is not necessarily mandated, but many manufacturers (if they have had any experience with recalls) they know that it is important to have traceability systems in place. This is especially true for consumer-driven products like cars where there could be accidents involved, or food products or pharmaceuticals where there could be health concerns.

While it might not be mandated by the government, automation systems may also be installed for reputational or image issues. Machine vision is all about quality control and precision inspection to make sure products are assembled and aligned properly, and that company brand and product aesthetic are maintained. Besides reputation, automation systems can also aid customer satisfaction, (for instance, by reducing scrap rates), so really it is again incumbent upon us as the supplier to help the end user justify our technology. And with the advent of technology becoming more powerful, more miniaturized, and more competitively priced, more businesses are now adopting it.

How is Microscan positioning itself to leverage IIoT to its own advantage? What does the IIoT mean to Microscan when it comes to product development today?

To explain Microscan’s position and philosophy on the Internet of Things, we are highly invested as producers of, well, the “thing”. We see the camera or the barcode reader as the “thing” that has intelligence, that is able to be connected, and thus it is imperative that we look at the IIoT with the concept of connectivity in mind. We manufacture our products in such a way that they can connect readily and easily across all modes of communication. This is to ensure that our products can transmit data to another system, like a PLC for instance, without compatibility obstacles. This facilitates the pervasiveness of data for widespread and variable use. Aside from this, we pack as much intelligence into our devices as possible, because it is the persistence of the “thing” that is really at the crux of our role in IIoT – the irreplaceable device. What you see in factory automation today is the flattening of control architectures with a lot more intelligence being embedded in the lowest sensors in the factory floor so they can connect peer to peer without peripheral equipment. With this architecture, you don’t have to go through a labyrinth of devices or communication media to make decisions. Ultimately, this simplification of the factory network is what is going to drive IIoT. The ability to transmit data efficiently and quickly to other devices that needed to consume it to optimize any function of manufacturing processes – that’s where we see our technologies playing a role. We aim to make our devices as intelligent as possible because these devices will persist. No matter what manufacturing scenario, businesses will always need sensors, like cameras and barcode readers, to acquire data from the factory floor to enable any process in the IIoT.

How far has track and tracing come along and how has IIoT impacted its development?

When I first started my journey with Microscan, someone told me that it would not be long before you will be able to track and trace a product from manufacture to the end user with the use of a smart phone. I have not seen this yet, but with the rate at which connectivity technology is evolving, I believe that this scenario will be entirely possible sooner than later. Privacy issues are the main obstacle in the road to achieving this because of all the data collected from various parties along the way. However, I think that the ability to track a product directly to a household and advise the consumer about the quality of the product, should there be any concerns about it, is going to happen eventually. This would be the ultimate display of the capabilities of the IIoT – a scenario where I can use a smart phone to access information acquired from barcode readers at the various stages in the manufacturing supply chain. So it is only a matter of time before the technology that is able to tie all these data together, and present them at the touch of a finger, is available.

Could you tell us more about the MicroHAWK platform then, and how in line is it with IIoT?

The MicroHAWK series is what I would call a complete product platform. We had four design principles that we were focused on. The first principle was to produce the smallest and most capable product on the market today. This is because customers are downsizing the footprints of their machines on manufacturing floors, so they need the most bang for the size of the product on the manufacturing line. Next is the ease of use, or “the out-of-box” experience. Our latest web interface for the MicroHAWK platform, WebLink, offers an unprecedented user experience and gives us patent-pending technology that also plays into IIoT. With regards to performance, we have upgraded our decoding algorithms to X-Mode 4.0, which is the most robust set of decoding algorithms in the industry today. During manufacturing operations, codes can get dirty or damaged, so having a robust set of decoding algorithms to read codes regardless of unpredictable results of environmental conditions was essential. The fourth design principle in the product design was modularity and scalability. We wanted to come up with products that leveraged a common software and hardware platform, providing customers with a range of products that could achieve different requirements with one highly-configurable toolset.

MicroHAWK is built on a common imaging engine at the core of the ID-20, -30 and -40 barcode readers, with two gigabytes of memory and interchangeable lenses across the board. The three readers differ in terms of connectivity. For instance, in the ID-40, there is an Ethernet port, whereas there is a Micro USB port in the ID-20. Other differences include the reader size, industrial rating, and illumination options. The choice of reader for a given application is dependent on the environment that they are going to function in. For instance, the ID-20 is better suited for a closed environment, for instance, a lab. The ID-40 would be best suited for more robust manufacturing spaces and applications where exposure to harsh manufacturing conditions is more likely.

On each reader, there is an embedded browser-based interface called WebLink. The actual Graphical User Interface (GUI) for WebLink (that is, the software) is embedded on the reader itself. Typically, with many barcode and vision products in the market, the software would be provided separately in a dongle which you would have to load onto a PC and interface it with the product. But in the case of the Microscan’s MicroHAWK series, by embedding the browser in the camera, you can bring up the interface on a PC or any device with a web browser without worrying about the stability of the software, its compatibility, or version, in the same way you would if it were loaded onto a PC separately. So as long as you have any sort of updated web browser at your disposal, all you need to do is enter the URL of the device and you can access the reader immediately.

Which verticals will the product be targeted at and what kind of offerings can it provide?

The ID-20 is targeted at instrument manufacturers, where we have had a lot of success in clinical and laboratory applications. We are working directly with those manufacturers to educate them further about the benefits of the ID-20; for example, the flexibility of its read range. Some of our competitors’ products, for instance, have had to use mirrors or other peripherals to achieve the same read performance that our readers can achieve at various mounting angles or orientations within equipment. The ID-40 would be targeted more towards sectors like the FMCG and electronics because of its high-speed Ethernet communication capability. The ID-30 would be somewhere in the middle of what the ID-20 and -30 can offer, and can cater to customers that are in both closed and open manufacturing environments. The ID-30 has serial communication, five volt input, and has an IP54 rating at a cost-efficient price point, so it has a competitive value standpoint.

LVS was recently acquired by Microscan. How does the LVS brand strengthen Microscan’s position in the machine vision market?

Traceability is critical when it comes to the health and pharmaceutical sector. Making sure that the barcodes are of good quality so that they can be tracked throughout the supply chain is critical. Recently, we acquired a company called Label Vision Systems, which verifies barcodes to barcode quality standards like ISO, GS1, and others, to meet the traceability requirements of certain industries. This is getting back to government mandates and regulatory requirements – they are hitting the medical device and pharmaceutical industry more directly to ensure that there are unique barcodes or identifiers on every product, and that those codes have sufficient quality so they can be read downstream. Ensuring readability of codes means that they need to be graded. So with Label Vision Systems, we now have a full range of technology intended specifically for grading barcodes and other identifiers to meet these customers’ needs.

Verification is a critical element in traceability. Verification uses machine vision technology, rather than barcode reading technology, because you are not just reading a code but rather analyzing its physical appearance as well as acquiring data for further code string format analysis. The synergy of LVS verification technology within the Microscan portfolio is compelling because Microscan was already providing verification, but this was primarily for direct part marks. By adding LVS products to our offerings, we expand our expertise from DPM verification to the verification of any barcode, printed or marked. LVS also allows us to expand our role in the manufacturing process into more areas of the supply chain. Take a medical device company as an example – LVS may be working with their packaging operations to make sure that the label on the outside of a box can be tracked. Meanwhile, we at Microscan are working with the same company ensuring traceability through the manufacturing operations of the product itself after it is packaged. With the acquisition, we can now offer all of these capabilities as a single solution, including the capability to do offline and inline verification through LVS products. Not only is our unified product line extremely synergistic, but LVS also addresses the same customers as us, so there is a lot of synergy from a market and customer standpoint as well.

How does Microscan differentiate itself from in the market?

Looking back at the four design principles that the MicroHAWK is based on, we are going to be smaller in terms of footprint, bigger on functionality as compared to other readers out there, and offer a much better “out-of-box” experience through superior ease of use, especially with WebLink. Compared to the competitors in the market today, we have better decoding performance and offer more modularity and scalability using a common imaging engine, and we are able to drive cost down as a result.

We also try to differentiate ourselves in how we work with our customers. Here at Microscan, we strongly believe in the element of trust playing a critical role in how we do business with our partner or our customer. We want them to trust us in providing them with accurate information through thick and thin to get their application right.

Strategically, we strive to bring to our customers the highest level of quality in the market in terms of products and service. For example, as part of our service, we can provide custom interfaces for specific applications, such as installations that enable real-time verification of barcode quality on products as they are passing down the production line. Wherever we see the customer or the market has a real need, we will take our core technology, maybe customize some software, and provide the right solution that will fit that application.

CHECK OUT THESE OTHER ARTICLES

● ITAP 2019: Stay Ahead, Stay Relevant

● Renishaw Shares Outlook On Vietnam And Philippines

● TRUMPF To Unveil Automated Mass 3D Printing Solution At Formnext 2019

● US Imposes 456 Percent Tariffs On Vietnam Steel

● Getting Ahead in the Medical Market

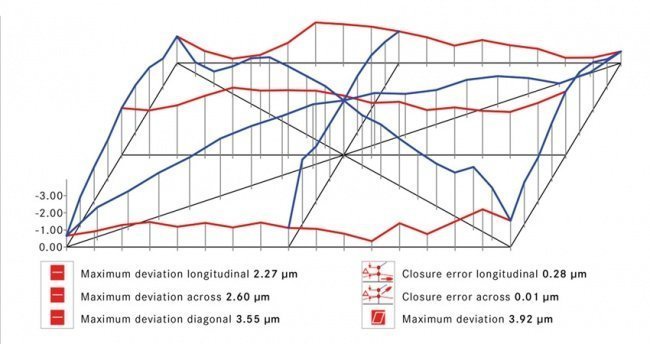

● 3D Goes Long-Range With The First Scanning Laser Tracker

● Interroll’s New Plant In Thailand Fully Operational

● Trumpf Partners With BeSpoon To Boost IIoT Portfolio

● LVD Announces Acquisition Of Italian Industrial Automation Firm, COMPAC S.r.l.

● Importance Of Process Control

WANT MORE INSIDER NEWS? SUBSCRIBE TO OUR DIGITAL MAGAZINE NOW!

FOLLOW US ON: LinkedIn, Facebook, Twitter